In this post, we’ll explore what a WMS ROI Calculator is and how it works. If you are in the market for a new WMS or looking to upgrade from your current system, you are in good company!

MarketsandMarkets™ projects the WMS market to grow from USD 4.0 billion in 2024 to USD 8.6 billion by 2029. This indicates that many companies will be seeking new WMS solutions over the next five years. Since a WMS is a long-term enterprise solution, typically integral to operations for over a decade, it’s crucial to evaluate what you are planning to invest and the return this investment will have on your business. To help you find the best WMS for your operations, Made4net offers a complimentary WMS Return on Investment (ROI) Calculator on our website. With it, supply chain professionals can determine specific returns that can be expected from a WMS investment.

What is a WMS ROI Calculator?

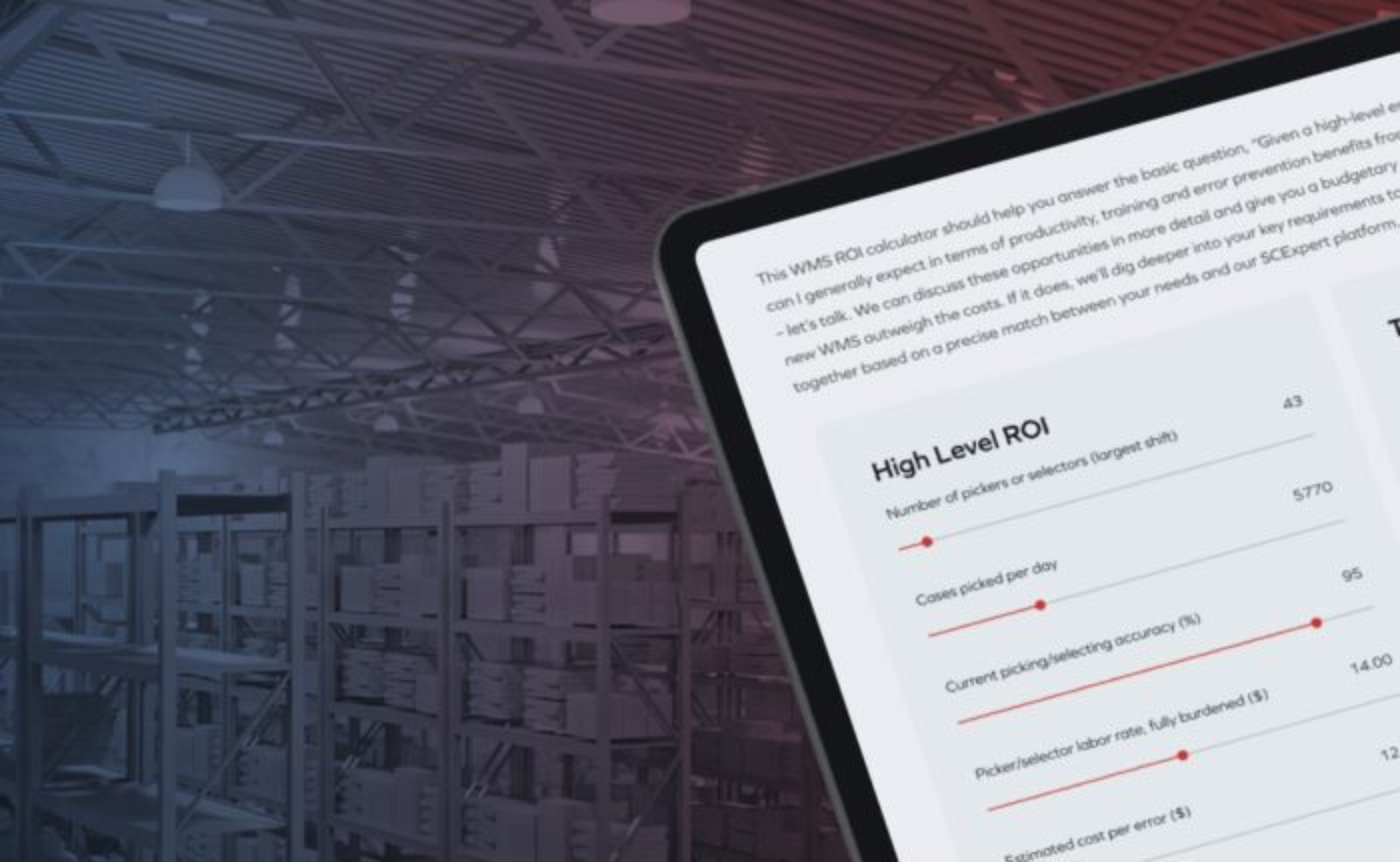

A WMS ROI Calculator can be used to determine whether or not a WMS is the right choice for your operation. It provides a thorough assessment of the current state of your warehouse operations and can demonstrate the potential return you might achieve with a new WMS. The Made4net WMS ROI Calculator uses calculations based on performance improvements that other Made4net customers have achieved. It’s a simple and reliable way of calculating risk versus reward. Whether you’re in the market for your operation’s first WMS, or looking to upgrade an existing system, the ROI Calculator can help ensure you’re making an informed decision.

How will a WMS benefit my operation?

Implementing a WMS can significantly enhance the operational efficiency, accuracy, and productivity of your warehouse, leading to overall business growth and improved customer satisfaction. Some key reasons to invest in a WMS include:

- Inventory Control and Accuracy: A WMS helps maintain accurate inventory records by providing real-time updates on stock levels, locations, and movements. This reduces errors associated with manual inventory tracking.

- Efficiency and Productivity: By automating various warehouse processes such as picking, packing, and shipping, a WMS improves the efficiency and productivity of warehouse operations. It optimizes the use of space and resources, leading to faster order fulfillment.

- Cost Reduction: Improved accuracy and efficiency result in cost savings. Reduced errors in inventory management lower the costs associated with stockouts, overstocks, and returns. Enhanced labor productivity and optimized use of warehouse space further contribute to cost reductions.

- Improved Customer Service: A WMS enables faster and more accurate order processing, leading to improved delivery times and order accuracy. This enhances customer satisfaction and can lead to increased customer loyalty.

- Data and Analytics: A WMS provides valuable data and analytics that help in making informed business decisions. It can track key performance indicators (KPIs), identify trends, and provide insights into areas that need improvement.

- Scalability: As your business grows, a WMS can scale with it. It can handle increased inventory levels, more complex processes, and larger order volumes without compromising efficiency or accuracy.

- Integration with Other Systems: A WMS can integrate with other business systems such as Enterprise Resource Planning (ERP) systems, Transportation Management Systems (TMS), and Customer Relationship Management (CRM) systems. This seamless integration ensures smooth data flow and enhances overall business operations.

- Compliance and Traceability: For industries with strict regulatory requirements, a WMS provides the necessary tools for compliance and traceability. It can track lot numbers, serial numbers, and expiration dates, ensuring that regulatory standards are met.

- Better Resource Management: A WMS helps in optimizing the use of labor and equipment. It can schedule and manage workforce activities, track performance, and ensure that resources are utilized efficiently.

- Improved Warehouse Layout: By analyzing warehouse activities and layouts, a WMS can suggest improvements in the arrangement of products, resulting in a more organized and efficient warehouse.

How do I calculate the ROI for a WMS investment?

Our ROI Calculator is designed to help you evaluate the financial impact of a WMS on your operations. It assesses how improvements in inventory control, accuracy, efficiency, and productivity can benefit your business. The tool provides a detailed breakdown of both inbound and outbound benefits.

On the Inbound side, the calculator will examine benefits in these processes:

- Pre-receiving

- Receiving

- Putaway

In order to calculate:

- Inbound Annual Errors Savings

- Inbound Productivity Savings

- Inbound Training Savings

On the Outbound side, the calculator will examine benefits in these processes:

- Replenishment

- Picking – Order Accuracy

- Picking – Improving Order Fill Rate

- VAS

- Staging

- Packing

- Loading

- Shipping

In order to calculate:

- Outbound Annual Errors Savings

- Outbound Productivity Savings

- Outbound Training Savings

Why should I use Made4net’s ROI Calculator?

Made4net’s WMS ROI Calculator will help you pinpoint the benefits of a new WMS, including improvements in productivity, training, and error prevention. With the ability to export visual summaries of your results, you can easily share high-level insights to build a strong case for a new WMS for stakeholders across warehouse management, operations, IT, and the C-suite.

If the savings from the ROI Calculator look compelling, you can schedule a complimentary session with our supply chain experts for a comprehensive ROI analysis. During this session, we’ll explore additional benefits in inventory, administration, and transportation to provide you with a complete budget estimate. Have questions? Contact us—we’re here to help!