Made4net WarehouseExpert™

Powerful, tier-one warehouse management software (WMS) for operations of all sizes

Everything You Need in a Warehouse Management System

End-to-End Platform

Reach true supply chain convergence, with a fully-integrated platform, including WMS, WCS, YMS, Labor, Routing and Proof of Delivery solutions.

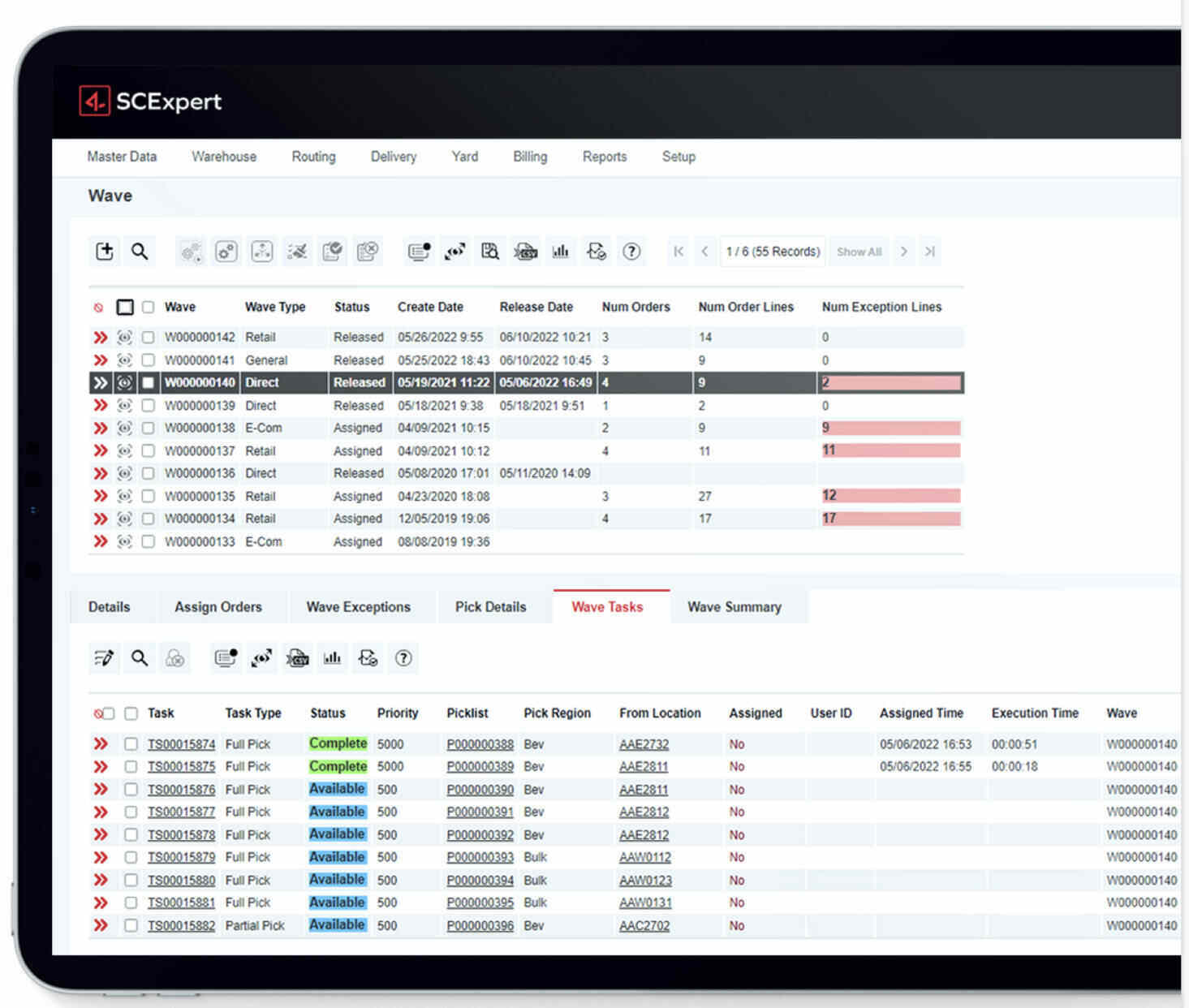

Optimal User Experience (UX)

Enhance user experience by allowing users to personalize their working environment with custom screens, dashboards, and workflows.

Real-Time Visibility and Reporting

Receive real-time updates on inventory levels, order fulfillment, and exception handling, along with historical insights for accurate decision-making.

Adaptable and Scalable WMS designed to grow with your distribution needs

Dynamic Warehouse Workflows

Configure workflows driven by business attributes, including fixed and variable attributes such as item, customer, vendor, location, lot, expiration date, serial, size, and color.

Seamless Integrations

Optimize productivity with a robust platform that seamlessly integrates with your tech stack and MHE, automation and robotics technology.

High Volume Capacities

Scale to meet the needs of facilities of all sizes and complexities, including distribution centers with MHE, automation, and robotics.

WCS and WES

Warehouse Control System and Warehouse Execution System to orchestrate MHE, robotics, automation and humans from a single platform for seamless efficiency.

Battle-Tested in Supporting High-Growth Industry Verticals

A Robust Warehouse Management System

What our customers are saying

Seamless Integration

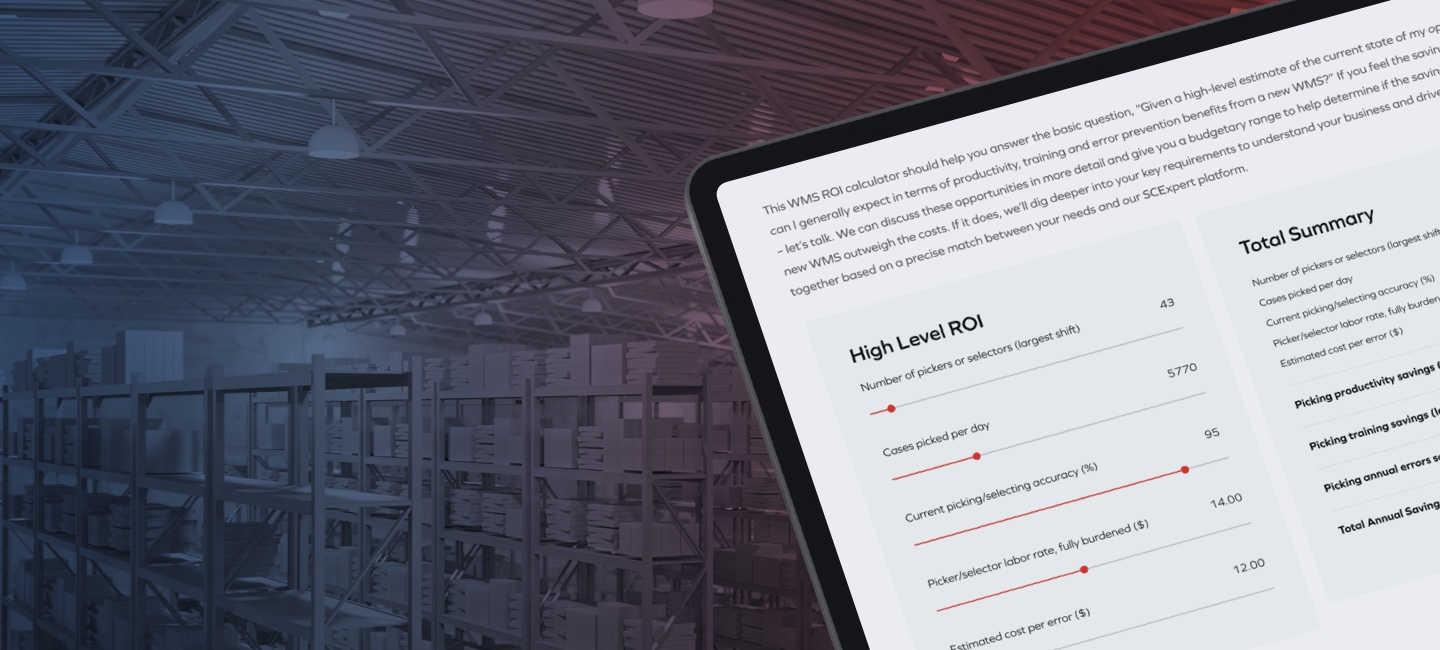

What’s your ROI?

Warehouse Management System FAQs

A Tier 1 warehouse management system is the most advanced solution for supply chain teams, handling complex operations across multiple facilities and integrations. It is highly customizable to meet specific operational needs.

A cloud-based warehouse management system (WMS) is ideal for businesses that prefer not to manage server hardware on-site, requiring only internet access to operate. Warehouse teams can use the web-based interface to run their operations.

Every facility has unique needs, but essential warehouse management features include:

- Flexible Integrations: The WMS should easily connect with carriers, suppliers, and other software like CRMs and ERPs.

- Automated Billing: The system should track activities by client, auto-generate invoices, and send them automatically.

- Analytics and Reporting: The software should offer robust, customizable reporting to deliver the right information, to the right people, at the right time.

- Ease of Use: The WMS should be user-friendly and adaptable to your unique needs with minimal source code changes.

- Billing Granularity: The solution should capture every revenue opportunity and ensure accurate billing by auditing operational processes, documenting each step taken for a customer, including value-added services, and aligning this data with customer contracts.

The cost of a WMS can vary widely depending on factors such as the system's features, the size of your warehouse, and whether it’s deployed on-premises or in the cloud. Typically, WMS solutions can range from a few thousand dollars for basic systems to tens or even hundreds of thousands for more advanced, customizable solutions. Additionally, ongoing costs such as subscription fees, maintenance, and training should be considered in the total cost. It's essential to assess your specific needs and request quotes from multiple vendors for an accurate estimate. Our guide to warehouse budgets provides more information.

If your WMS has run its course, this is an excellent opportunity to look at all the available options to see what is best for your needs today, as well as your growth plans down the line. With all the technological improvements made to warehouse management systems in the last decade alone, it’s worthwhile to look at everything available, not only the upgrade to your current system.

Here are some factors to consider when making this decision:

- The cost of upgrading: Upgrading to a new version of your current WMS may be less expensive than buying a new WMS. However, you should also consider the cost of maintenance and support for the new version.

- The features and functionality of the new WMS: Make sure that the new WMS has the features and functionality that you need. If the new WMS does not have the features and functionality that you need, you may be better off buying a new WMS.

- The ease of migration: If you decide to buy a new WMS, you will need to migrate your data from your old WMS to the new WMS. Make sure that the new WMS has a migration tool that will make this process easy.

Choosing the right WMS involves several key steps:

- Assess Your Needs: Identify your specific requirements, such as inventory volume, complexity, and types of products.

- Evaluate Features: Look for essential features like inventory tracking, order management, reporting and analytics, and integration capabilities with existing systems.

- Consider Scalability: Choose a WMS that can grow with your business and adapt to changing needs.

- Request Demos: Evaluate potential solutions through demonstrations to understand their functionality and user interface.

- Check References: Speak with other users or read reviews to gauge the reliability and customer support of the WMS provider.

- Calculate Total Cost: Consider not only the upfront costs but also ongoing expenses, such as maintenance and support, to ensure the solution fits your budget.

Check this out in your analysis: The Gartner® Magic Quadrant™ for Warehouse Management Systems (WMS) is a one-of-a-kind report that uses a uniform set of evaluation criteria to help you quickly determine how well technology providers are performing against Gartner’s market view. We highly recommend incorporating this research into your search!