Every product you order online—every shipment that arrives on time, every inventory count that’s accurate—depends on software most customers never see. That software is a warehouse management system (WMS), the operational brain that orchestrates modern distribution and fulfillment operations.

A WMS does far more than track inventory location. It directs every movement within the warehouse: receiving, putaway, picking, packing, and shipping. It coordinates labor and automation, optimizes workflows in real time, and provides the visibility that turns a warehouse from a cost center into a strategic asset.

In this guide, we’ll explain what a WMS actually does, the challenges it solves, how it works behind the scenes, and the core capabilities that separate basic inventory software from true warehouse management platforms.

- What Does WMS Stand For? What Does WMS Mean?

- What is a Warehouse Management System (WMS)?

- What is the Purpose of a Warehouse Management System?

- Where Does a WMS Fit in the Supply Chain?

- What Are Common Challenges in Warehouse Management?

- How Does a Warehouse Management System (WMS) Tackle Top Challenges?

- What Does a Warehouse Management System Do? How Does it Work?

- What Are the Core Features of a Warehouse Management System?

- Who Can Benefit From a Warehouse Management System?

- Warehouse Management System User Example

- The Future of Warehouse Management Systems

What Does WMS Stand For? What Does WMS Mean?

A WMS, or warehouse management system, is software that controls and optimizes warehouse operations from receiving through shipping.

While the acronym is straightforward, what qualifies as a true WMS isn’t always clear. Basic inventory tracking tools are sometimes called WMS platforms, but genuine warehouse management systems provide comprehensive operational control: inventory positioning, task orchestration, labor coordination, automation integration, and real-time performance visibility.

The distinction matters because the capabilities gap between basic inventory software and enterprise WMS platforms directly impacts operational efficiency, accuracy, and scalability.

What is a Warehouse Management System (WMS)?

A warehouse management system serves as the operational control center for distribution and fulfillment operations. It orchestrates every movement within the facility—from the moment goods arrive at receiving docks through final shipment to customers.

At its core, a WMS provides real-time visibility into inventory location and status, whether stored in the warehouse or in transit between facilities. But visibility alone isn’t enough. Modern WMS platforms actively direct operations: optimizing putaway locations, routing picking tasks efficiently, coordinating packing workflows, and integrating with automation equipment. The result is reduced errors, improved labor productivity, and faster order fulfillment—all critical factors in meeting today’s delivery expectations.

What is the Purpose of a Warehouse Management System?

The primary purpose of a WMS is to transform warehouse operations from reactive to proactive—replacing guesswork with data-driven decisions and manual coordination with automated orchestration.

Specifically, a WMS delivers:

- Inventory accuracy and visibility – Real-time tracking of every SKU, location, and quantity eliminates stockouts and reduces excess inventory

- Optimized picking and fulfillment – Intelligent routing and task prioritization minimize travel time and accelerate order processing

- Labor efficiency – Balanced workload distribution and performance tracking maximize workforce productivity

- Error reduction – System-guided workflows and automated validation prevent costly picking and shipping mistakes

- Operational intelligence – Analytics and reporting identify bottlenecks and improvement opportunities

Together, these capabilities enable warehouses to fulfill orders faster, more accurately, and at lower cost—turning the warehouse from a necessary expense into a competitive advantage.

Where Does a WMS Fit in the Supply Chain?

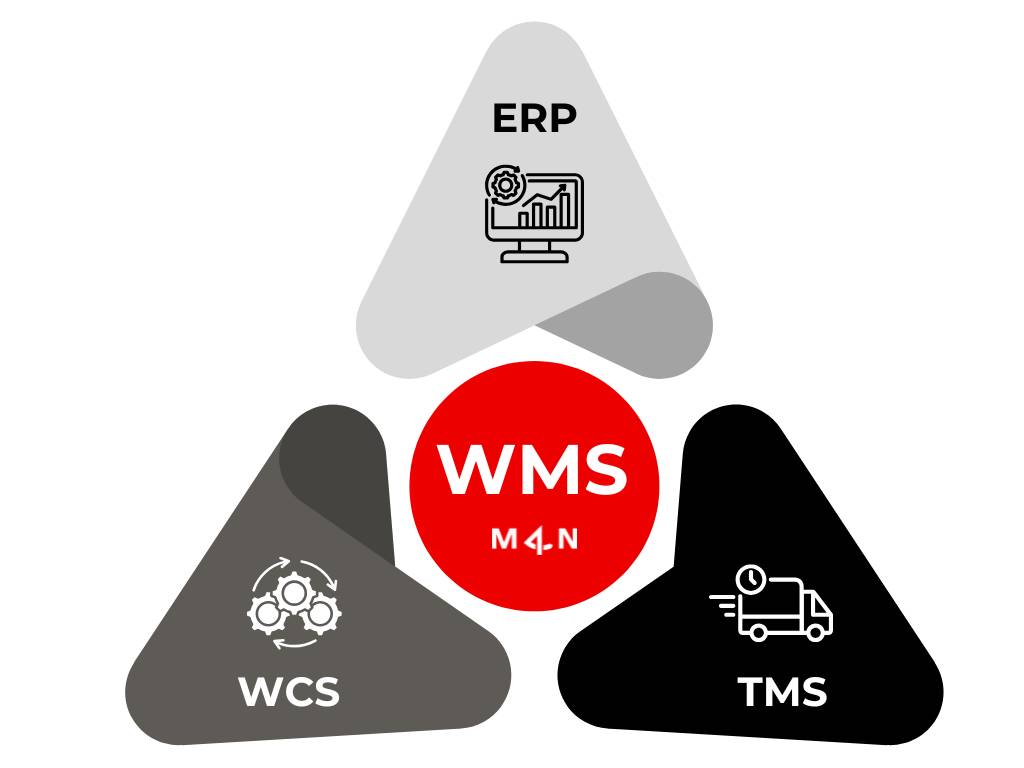

A WMS occupies the critical middle layer of the supply chain technology stack—sitting between enterprise resource planning (ERP) systems and warehouse floor operations.

Upstream Integration: The WMS receives orders, inventory data, and business rules from your ERP or order management system (OMS). When a customer places an order, the ERP creates the transaction while the WMS determines how to fulfill it most efficiently.

Warehouse Operations: Within the four walls, the WMS controls everything: directing receiving teams where to put goods, telling pickers which items to retrieve and in what sequence, coordinating packing workflows, and scheduling outbound shipments. For automated facilities, the WMS communicates with warehouse control systems (WCS) and robotics platforms to coordinate human and automated resources.

Downstream Coordination: Once orders ship, the WMS feeds fulfillment data back to the ERP for invoicing and inventory updates, while also providing tracking information to transportation management systems (TMS) and customer-facing order portals.

This integration creates end-to-end visibility and coordination—ensuring that what happens on the warehouse floor aligns with enterprise business objectives and customer expectations.

What Are Common Challenges in Warehouse Management?

Modern warehouse operations face mounting pressure from multiple directions—rising costs, accelerating delivery expectations, and increasing operational complexity. These challenges compound quickly, impacting productivity, profitability, and customer satisfaction.

- Inaccurate Order Fulfillment: Picking, packing, and shipping errors lead to returns, customer dissatisfaction, and lost revenue. Manual processes and high SKU complexity make mistakes inevitable—yet even a 2-3% error rate creates significant costs and damages customer relationships.

- Receiving and Putaway Bottlenecks: Poor coordination between receiving and storage operations creates cascading delays. When incoming goods sit waiting for putaway, valuable dock space gets consumed, inventory accuracy suffers, and downstream fulfillment slows.

- Seasonal Demand Volatility: Peak seasons stress every aspect of operations. Without flexible systems and scalable processes, warehouses face backlogs, delayed shipments, and overwhelmed staff—exactly when performance matters most.

- Omnichannel Complexity: Fulfilling orders across retail stores, e-commerce, marketplaces, and wholesale channels multiplies operational complexity. Each channel has different requirements for packaging, labeling, shipping methods, and returns processing—creating confusion and inefficiency when managed manually.

- Persistent Labor Challenges: Warehouse labor represents up to 50-70% of total operating costs, yet finding and retaining skilled workers remains difficult. High turnover drives up training costs, reduces productivity, and creates institutional knowledge gaps that impact quality.

Manual processes and disconnected systems can’t keep pace with these challenges. A warehouse management system addresses them systematically—replacing reactive problem-solving with proactive operational control.

How Does a Warehouse Management System (WMS) Tackle Top Challenges?

A WMS transforms operational challenges into competitive advantages through five core capabilities:

- Enhanced Inventory Accuracy: Real-time tracking, barcode validation, and automated cycle counting eliminate the discrepancies that plague manual systems. Businesses typically see inventory accuracy improve from 80-85% to 99%+, virtually eliminating stockouts caused by system errors and reducing excess inventory from safety stock buffers.

- Accelerated Order Fulfillment: Intelligent picking strategies (wave, batch, zone), optimized routing, and task prioritization reduce travel time and processing steps. Orders that previously took hours to fulfill can be completed in minutes—while maintaining or improving accuracy.

- Optimized Space Utilization: Dynamic slotting algorithms position fast-moving items in accessible locations while maximizing vertical space and storage density. The same physical footprint handles 20-40% more inventory, often delaying or eliminating the need for facility expansion.

- Improved Labor Productivity: Task interleaving, workload balancing, and performance visibility keep workers productive throughout their shifts. By eliminating wasted motion and providing clear priorities, a WMS can improve picking productivity by 25-50% without adding headcount.

- Operational Scalability: Cloud-based WMS platforms handle seasonal peaks, new fulfillment channels, and facility expansion without system limitations. The same software that manages 100 daily orders scales seamlessly to 10,000—adapting workflows and resources to match demand.

These capabilities work together, creating compounding benefits that extend far beyond addressing individual pain points. The result is an operation that’s faster, more accurate, more flexible, and more profitable.

What Does a Warehouse Management System Do? How Does it Work?

A WMS orchestrates core functions in the warehouse through five interconnected processes:

- Receiving & Inventory Control – Directs putaway, tracks inventory in real time, and maintains location accuracy across the facility

- Task Assignment & Labor Management – Dynamically assigns work based on priorities and resources, balancing productivity while tracking performance

- Location & Identification – Assigns unique identifiers to every location and item, enabling instant lookup and movement validation

- Order Fulfillment – Determines optimal picking strategies, generates efficient paths, and validates accuracy throughout the process

- Packing & Shipping – Optimizes packaging through cartonization algorithms, generates compliant labels, and coordinates carrier logistics

What Are the Core Features of a Warehouse Management System?

When it comes to WMS solutions, there are various solution tiers, but we believe top-tier WMS platforms offer the following essential capabilities that form the foundation of modern warehouse operations:

Core WMS Feature #1: Inventory Management & Visibility

- Real-time tracking across all locations, SKUs, lots, and serial numbers

- Dynamic slotting that optimizes storage based on velocity and characteristics

- Automated cycle counting to maintain accuracy without disruptive physical inventories

Core WMS Feature #2: Order Fulfillment & Execution

- Multiple picking strategies (discrete, batch, wave, zone, cluster) with intelligent selection

- Optimized pick paths that minimize travel time and maximize efficiency

- Task interleaving to combine putaway, replenishment, and picking into efficient sequences

Core WMS Feature #3: Receiving & Putaway

- Guided receiving workflows with quality checks and cross-docking decisions

- Intelligent putaway direction based on product velocity, size, and layout

- Cross-docking capabilities to move goods directly from receiving to shipping

Core WMS Feature #4: Packing & Shipping

- Cartonization algorithms that optimize packaging and reduce shipping costs

- Multi-carrier integration for rate comparison, label printing, and tracking

- Shipping verification through weight checks and automated quality controls

Core WMS Feature #5: Labor Management

- Performance tracking against standards with real-time feedback

- Dynamic workload balancing across available resources based on skills and availability

- Productivity analytics that identify top performers and training opportunities

Core WMS Feature #6: Integration & Technology

- ERP/OMS connectivity for seamless order and inventory data exchange

- WCS integration to coordinate automation equipment and material handling systems

- Mobile-first interfaces with barcode/RFID scanning and voice-directed workflows

Core WMS Feature #7: Analytics & Reporting

- Real-time dashboards displaying key operational metrics and exceptions

- Customizable reports for inventory, fulfillment, labor, and performance analysis

- Configurable business rules that adapt workflows without custom coding

According to Amit Levy, Made4net’s EVP of Sales and Strategy, “The best WMS platforms don’t just check these boxes—they integrate these features seamlessly to create coordinated workflows that deliver measurable improvements in speed, accuracy, and efficiency.”

Who Can Benefit From a Warehouse Management System?

Any organization managing inventory and fulfilling orders can benefit from a WMS—but the system you need depends on your operational complexity. Choosing the right solution means matching capabilities to your current reality while planning for future growth.

WMS: The Complexity Spectrum

Level 1: Basic Manual Warehouses

Fixed storage, simple workflows, low SKU counts → Cloud-based WMS with core inventory tracking, order management, and barcode scanning

Level 2: Multi-Location Operations

Multiple zones, higher volumes, basic slotting → Dynamic location management, directed picking, wave/batch capabilities

Level 3: Dynamic Fulfillment

Multiple picking strategies, omnichannel, value-added services → Advanced task orchestration, flexible workflows, labor management, integrated transportation

Level 4: Automation-Enabled

Conveyors, sortation, modest robotics → WCS integration, equipment coordination, hybrid resource management, real-time monitoring

Level 5: Highly Automated

AS/RS, extensive robotics, goods-to-person → WES capabilities, multi-system orchestration, predictive analytics, AI-driven optimization

The most expensive mistake isn’t underbuying—it’s mismatching system complexity to operational needs. A Level 1 operation doesn’t need Level 5 capabilities, and a Level 4 operation can’t succeed with Level 2 software. The best WMS investment delivers immediate ROI at your current complexity level while providing a clear upgrade path as your operation evolves.

Warehouse Management System User Example

Material Bank, a leading material sample delivery service for architects and designers, partnered with Made4net to transform its high-volume fulfillment operations. The company needed to maintain next-day delivery commitments while scaling to handle increasing order volumes—all with near-perfect accuracy.

The Results:

- 99.98% Order Accuracy: Material Bank delivers architectural and design samples with near-perfect precision—critical when professionals depend on receiving exact materials for client presentations and project specifications.

- 20-30% Productivity Improvement: Intuitive system design reduced employee training time from weeks to days, while streamlined workflows increased throughput without adding headcount.

- Next-Day Delivery at Scale: Advanced picking optimization and order management enable Material Bank to ship 98% of packages via priority overnight service for 10:30 AM delivery—maintaining this commitment even during peak demand periods.

- Reduced Environmental Impact: Intelligent order consolidation algorithms automatically combine related items, reducing packaging materials and shipping waste while lowering transportation costs.

- Continuous Optimization: Weekly collaboration sessions with Made4net’s development and support teams ensure the system evolves with Material Bank’s growing operational requirements and business objectives.

The Future of Warehouse Management Systems

Warehouse management systems have transformed from inventory tracking tools into intelligent orchestration platforms that control real-time execution, support decision-making, and coordinate complex fulfillment operations.

Mounting pressures—faster delivery expectations, rising labor costs, and automation integration requirements—have driven this evolution. But as Levy explains, “The next wave of innovation will be even more transformative. Artificial intelligence, autonomous operations, and cloud-native architectures are enabling WMS platforms to become truly intelligent, extensible, and adaptive to multi-channel fulfillment environments.”

Here’s how these forces are reshaping warehouse management:

The Future of Warehouse Management Systems: AI-Powered Predictive Operations

Next-generation WMS platforms will shift from reactive problem-solving to predictive intelligence. Machine learning algorithms will analyze historical patterns, real-time conditions, and external factors to anticipate demand fluctuations, optimize inventory positioning proactively, and identify potential bottlenecks before they impact performance.

AI will also democratize operational intelligence through natural language interfaces. Supervisors can ask questions like “Why is this order delayed?” or “What’s causing the bottleneck in Zone 3?” and receive contextual, data-driven answers—making sophisticated analytics accessible to everyone, not just technical specialists.

The Future of Warehouse Management Systems: Autonomous Operations and Hybrid Orchestration

As warehouses deploy more autonomous mobile robots (AMRs), automated storage and retrieval systems (AS/RS), and robotic picking solutions, WMS platforms are evolving into sophisticated orchestration engines that seamlessly coordinate human workers and automated equipment.

Future systems will intelligently assign tasks to the optimal resource—human or machine—based on real-time conditions, equipment availability, and workload balance. This hybrid approach maximizes the strengths of both automation speed and human problem-solving rather than simply replacing workers with robots.

The Future of Warehouse Management Systems: Cloud-Native Architecture and Composability

Cloud-native, microservices-based WMS architecture delivers unprecedented flexibility. Organizations can deploy new functionality rapidly, scale resources dynamically during peak periods, and integrate best-of-breed solutions without monolithic system constraints.

Composable WMS platforms enable businesses to assemble exactly the capabilities they need—selecting modules for specific functions while maintaining seamless integration. This approach reduces implementation timelines, lowers total cost of ownership, and ensures systems evolve as business requirements change.

The Future of Warehouse Management Systems: Emerging WMS Capabilities

Ready to Transform Your Warehouse Operations?

From their origins as basic inventory tracking systems in the 1970s to today’s intelligent orchestration platforms, warehouse management systems have become the operational foundation of modern fulfillment. Regardless of how much automation, robotics, or AI your operation deploys, a sophisticated WMS remains essential—coordinating every movement, decision, and resource from receiving dock to delivery truck.

The question isn’t whether you need a WMS, but whether your current system can support where your business is heading. As customer expectations intensify, labor markets tighten, and technology capabilities expand, the gap between basic and advanced WMS platforms directly impacts your competitive position.

Made4net’s WarehouseExpert™ delivers the intelligence, flexibility, and scalability that modern fulfillment operations demand. Schedule a demo to see how our WMS platform can transform your warehouse from a cost center into a strategic advantage.