In today’s business climate, 3PLs face numerous challenges, including labor constraints and real estate limitations. To optimize a 3PL’s productivity and efficiency, operators need to consider technology (like 3PL warehouse management software); hardware and automation; labor optimization; and, of course, maximize warehouse space utilization. Efficiently utilizing warehouse space is essential for maximizing productivity, improving customer satisfaction, and driving business growth.

In this blog post, we’ll explore:

- What is warehouse space utilization?

- Why is warehouse space utilization important to optimize?

- How do you improve warehouse space utilization?

What is Warehouse Space Utilization?

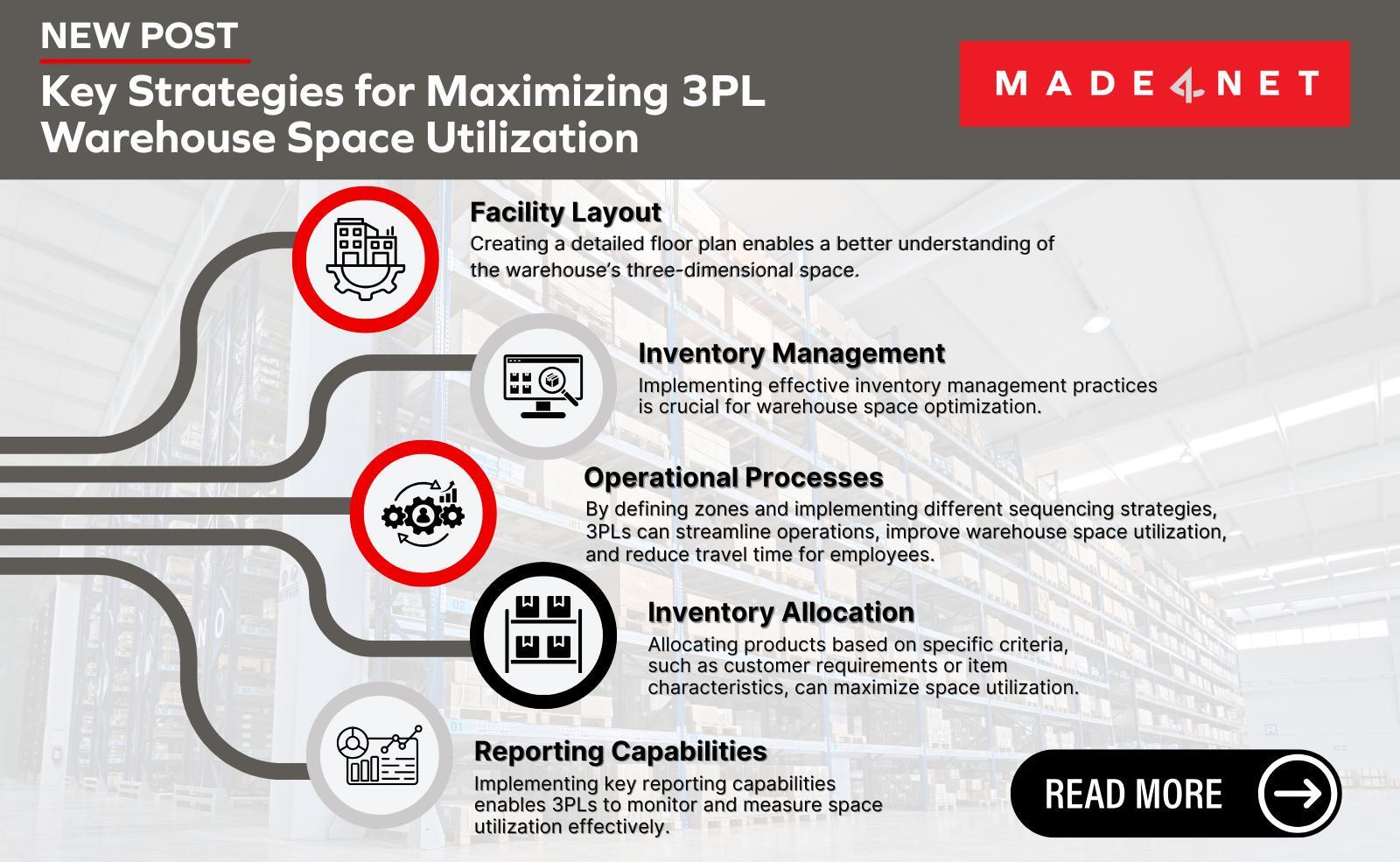

Warehouse space utilization refers to the ratio of occupied storage space to the total storage space in a warehouse. To effectively optimize space utilization, it is crucial to consider factors such as facility layout, inventory management, operational processes, inventory allocation, and reporting capabilities.

Why is Warehouse Space Utilization Important to Optimize?

Warehouse space utilization is a critical factor for 3PL providers because it directly impacts operational efficiency, cost savings, and scalability. As 3PL providers manage the storage and distribution of goods for various clients, optimizing warehouse space helps maximize inventory flow while minimizing wasted space. Efficient warehouse space utilization enables 3PLs to move and store more goods in a smaller area, which reduces the need for additional warehousing, ultimately cutting down on overhead costs.

Properly optimized warehouse space ensures a more organized warehouse layout, allowing for faster retrieval times, streamlined order picking, and reduced handling costs. It also aids in inventory accuracy, helping prevent stockouts or overstocking by providing a clear overview of available space and current stock levels.

Moreover, optimized warehouse space supports scalability. As businesses grow, the ability to adapt and efficiently use available space allows 3PLs to accommodate increased product volumes without needing to invest in more warehousing space. This is especially important in an era of rising real estate costs.

How Do You Improve Warehouse Space Utilization?

Strategies to (Help/Maximize) Your Warehouse Space Utilization

Warehouse Space Utilization Strategy #1: Facility Layout

Creating a detailed floor plan enables a better understanding of the warehouse’s three-dimensional space. Physical barriers, such as roll-up doors or separate buildings, can be considered to define sections and zones within the warehouse. By strategically separating different products and customers, 3PLs can improve operational efficiency and prevent cross-contamination.

Warehouse Space Utilization Strategy #2: Inventory Management

Implementing effective inventory management practices is crucial for warehouse space optimization. This involves establishing a geographic cycle count program to maintain accurate inventory data. Consolidating products and avoiding fragmented storage across multiple locations can minimize space wastage and enhance productivity.

Warehouse Space Utilization Strategy #3: Operational Processes

Utilizing directed put-away techniques allows the system to determine the best storage location for products. By defining zones, implementing different sequencing strategies, and considering storage type zoning (such as floor storage and rack storage), 3PLs can streamline operations, improve warehouse space utilization, and reduce travel time for employees.

Warehouse Space Utilization Strategy #4: Inventory Allocation

Allocating products based on specific criteria, such as customer requirements or item characteristics, can maximize space utilization. Clean allocation, where picking is done from the same location until it is empty, minimizes partial pallets and optimizes space. Setting up template allocation rules for different scenarios and considering sequencing strategies can further enhance space utilization.

Warehouse Space Utilization Strategy #5: Reporting Capabilities

Implementing key reporting capabilities enables 3PLs to monitor and measure space utilization effectively. Empty location reports help identify available space for new products or customers. Stock term assessments help optimize space based on product turnover rates. Productivity reports highlight barriers and inefficiencies, enabling process improvements. Utilization reports provide insights into the availability and usage of different storage locations.

Conclusion

Efficient warehouse space utilization is crucial for 3PLs to optimize warehouse operations and meet customer demands. By paying close attention to facility layout, inventory management, operational processes, and inventory allocation, and leveraging reporting capabilities, 3PLs can maximize their warehouse space. This not only improves productivity but also leads to cost savings, better customer service, and a more favorable employee experience. Embracing these strategies will position 3PLs for success in a competitive business environment.

For more guidance on Strategies to Maximize Your Warehouse Space Utilization, check out this webinar presented in conjunction with our partners, the International Warehouse Logistics Association (IWLA).You may also benefit from chatting with a 3PL consultant that can share tips and expertise to ensure you’re utilizing your space effectively.