All shippers have performance metrics to meet. Whether they are shooting for on-time in-full (OTIF), order accuracy, days to delivery, returns turnaround time, or meeting next-day shipping commitments, these goals are becoming increasing harder to meet as costs soar, labor remains scarce and consumer expectations continue to rise.

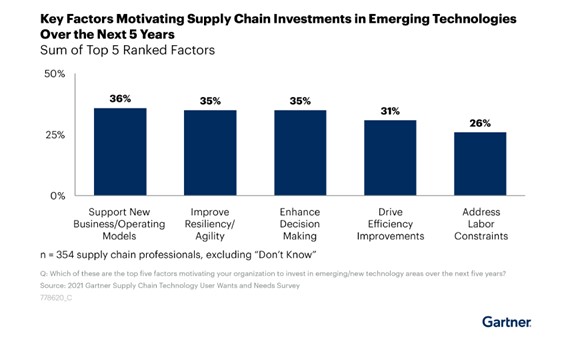

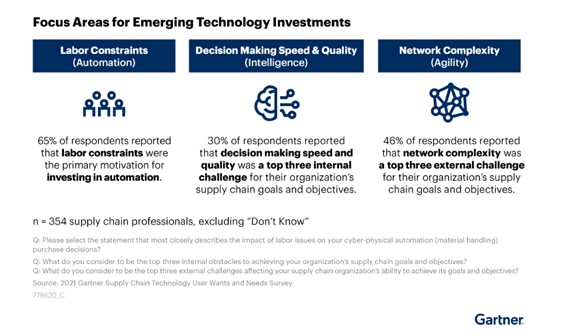

According to Gartner’s Predicts 2023: Supply Chain Technology report, “Growing complexity and volatility are forcing supply chain organizations to adjust their technology investments to align with their needs for resiliency, agility and intelligent operations.” According to a survey of 354 supply chain professionals sited in the report, factors driving investments include support new business; improve process efficiency/productivity; enhance decision making; improve resiliency/ agility, and address labor constraints.

Having an integrated WMS and TMS stack is one area of investment that is helping supply chain leaders address these needs.

Function of a WMS

A warehouse management system (WMS) is an execution platform that optimizes supply chain fulfillment operations from the distribution center to end consumer and offers visibility into a business’ entire inventory.

Function of a TMS

A transportation management system (TMS) is a logistics platform that uses technology to help businesses plan, execute, and optimize the physical movement of goods, both incoming and outgoing, and making sure the shipment is compliant, proper documentation is available.

WMS/TMS Integration

When it comes to order fulfillment, expectations continue to rise. According to JP Wiggins, Vice President of Corporate Development at 3Gtms, “Today’s shippers need a powerful control tower from which they can orchestrate fulfillment and respond to challenges as they arise, so they never disappoint. A fully integrated WMS/TMS solution gives them the power they need.” A WMS manages goods in the yard and within the distribution center. A TMS manages everything in transit. When orders can flow seamlessly between the two systems, a shipper can manage their customers’ orders from the point of receipt to the point of delivery without breaking a sweat.

Wiggins explains that on the outbound side, there are two ways a WMS and TMS can come together to optimize distribution. In the first scenario, the WMS sends a notice of an outbound load to the TMS and from there the TMS maps out the optimal route for transport of that load. Loads may be FTL or LTL and the routing may be direct or involve multiple stops, but the TMS does the heavy lifting to be sure once picked and ready to go, shipments are correctly routed to make service delivery windows as cost effectively as possible.

In the second scenario, the TMS gets involved earlier in the process. In this case, the orders pass through the TMS first. The system analyzes the orders, considers destinations and delivery times, plans routes and consolidates orders according to mode before the orders are dropped into the WMS. According to Wiggins, “Ninety plus percent of our customers follow this process as this type of order flow is useful in dynamic environments where orders are added or changed frequently and multi-stop truckload and pool distribution are in effect.” The route planners use TMS optimization to plan loads, but also have flexibility to consider changes. In this scenario, loads can are dropped to the WMS with mode and carrier known.

On the inbound side, an integrated TMS/WMS can offer improved visibility into all inbound shipments so a shipper can stay on top changes (like delays or early arrivals) and plan labor accordingly.

Benefits of WMS/TMS Integration

In addition to the many advantages and benefits of using a warehouse management system, a WMS/TMS integration leads to improved labor scheduling and equipment management. Tight integration also ensures shippers can react faster and more accurately to unexpected events.

Improved Labor Scheduling and Equipment Management:

Most warehouses have dynamic order patterns, meaning very few know all shipments for the month at the start of the month. This leads to fluctuating labor and equipment requirements. You cannot achieve effective route planning in your TMS and effective labor planning in your WMS without coordinating the two systems. The more dynamic the environment, the tighter the integration needs to be.

React Faster and More Accurately to Unexpected Events:

WMS/TMS integration delivers real-time visibility which is helpful in reacting to changes. In most warehouses, a 2-hour delay from a carrier can dramatically change the day. When you can see the delay in advance, you can react and minimize its impact. Labor can be better planned, door utilization is higher, outbound staging areas can remain clear, and more.

The benefits of real-time visibility also carry over to improved order management, as with an integrated WMS/TMS you get a more granular look at inbound in-transit shipments. Most WMS solutions can see shipment data, but cannot translate that shipment data into order data. A TMS has the ability to discern which orders are on which trucks and can inform the WMS as to when they will be arriving. This end-end order fulfillment visibility can lead to improved operations management.

3Gtms/Made4net

Many warehouse management systems can integrate with transportation management systems, but not all. If you are looking for tight integration, you might want to buy solutions from vendors with an established partnership.

3Gtms and Made4net have integrated their TMS and WMS solutions to give shippers more control and better decisions making power. Both Made4net and 3Gtms are committed to delivering real time supply chain software that is faster and easier to deploy. Each delivers a flexible, rules-based platform that allows companies to configure, rather than code. This means customers can tailor the joint solution to meet their needs without relying on costly developers.

According to Amit Levy, EVP, Customer Solutions and Strategy at Made4net, “The 3Gtms partnership means shippers now have a WMS and TMS that work together as unified solution to deliver complete visibility and control of orders from the point of receipt to the point of delivery. This partnership supports the need for supply chains to make faster, more accurate decisions in a shipping environment that continues to be highly volatile.”

But regardless of the vendors you choose, integrating your WMS and TMS is a smart choice. When TMS and WMS work together, a shipper can track shipments up and down the supply chain. At the end of the day, this approach enables a better use of resources, labor, improved decision-making capabilities and more agility – all key reasons driving technology investments today.

Interested in learning more about the WMS market? You can download a complimentary copy of the 2022 Gartner® Magic Quadrant™ for Warehouse Management Systems and learn more about Made4net’s capabilities, among other provider offerings here.

Sources:

Gartner, Predicts 2023: Supply Chain Technology, Published 28 November 2022

By Analyst(s): Dwight Klappich, Christian Titze, Tim Payne, Amber Salley, Simon Tunstall

Gartner, Magic Quadrant for Warehouse Management Systems, 01 June 2022, Simon Tunstall | Dwight Klappich | Rishabh Narang

Gartner Disclaimer:

GARTNER is a registered trademarks and service mark, and MAGIC QUADRANT is a registered trademark of Gartner, Inc. and/or its affiliates in the U.S. and internationally and are used herein with permission. All rights reserved.

Gartner does not endorse any vendor, product or service depicted in its research publications, and does not advise technology users to select only those vendors with the highest ratings or other designation. Gartner research publications consist of the opinions of Gartner’s research organization and should not be construed as statements of fact. Gartner disclaims all warranties, expressed or implied, with respect to this research, including any warranties of merchantability or fitness for a particular purpose.