For enterprise businesses, effective warehouse management—either through on-premise or cloud-based warehouse management systems—is critical to stay competitive. But, selecting and implementing the right WMS for your enterprise company is no small task. Many organizations face challenges throughout the process, which can hinder success if not approached carefully.

In this blog, we will explore the essential aspects of an enterprise WMS, including what it is, its importance in modern supply chain management, and key considerations for selecting the right system for your business. We’ll cover:

- What is an enterprise WMS?

- What should businesses consider when selecting an enterprise WMS?

- Enterprise WMS implementation lessons:

- Establish a selection criteria for wms vendors

- Evaluate vendors based on functional requirements and conduct demos to find the right fit

- Create a robust implementation integration plan and prime the warehouse environment before deployment

- Facilitate continuous training to upskill users and dedicate internal teams to steer the implementation

- Hire an experienced implementation partner and leverage external support for seamless integration

What is an Enterprise WMS?

An enterprise WMS is designed to manage and optimize the day-to-day operations of a warehouse or distribution center for large, enterprise businesses. It is a core component of the broader supply chain management process, providing functionalities to track, manage, and streamline processes related to inventory control, order fulfillment, shipping, receiving, and storage. Ultimately, an enterprise WMS helps businesses handle complex operations to improve efficiency and productivity.

What Should Businesses Consider When Selecting an Enterprise WMS?

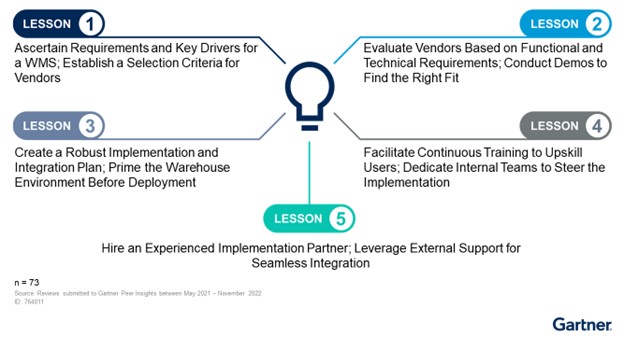

When it comes time to select and implement a new enterprise WMS, there are countless pitfalls supply chain leaders can encounter. If you’d like to avoid them, preparation is key! Fortunately, Gartner Inc. recently published their report, Gartner® Peer Insights™ ‘Lessons Learned: Implementing Warehouse Management Systems. In this report, Gartner analyzes 73 peer insights reviews with regard to implementing a WMS. “The report focuses on the responses to the questions: ‘If you could start over, what would your organization do differently?’ and ‘What one piece of advice would you give other prospective customers?’ These learnings provide a comprehensive look into the WMS selection and implementation process.

Read on for highlights of the five lessons learned, our take on each, and top tips from your peers.

Gartner Peer Insights ‘Lessons Learned’: Implementing Warehouse Management Systems

Lessons learned in this report are grouped into five categories:

Enterprise WMS Implementation Lesson #1: Establish a Selection Criteria for WMS Vendors

“Peers suggest supply chain technology leaders to identify and document functional and technical requirements for a new or replacement WMS. The point of departure should be to understand the current state of operations and foresee a future state of the organization, so that a clear selection criteria for vendors emerges.”

OUR TAKE:

Selecting the right enterprise WMS requires a deep understanding of what you need – ambiguity has no place here. Create an RFX that outlines and matches both your short- and long-term goals. This means defining all functional requirements, including all traditional enterprise WMS functions from inside the warehouse, plus activities related to yard management, dock scheduling, labor reporting, different picking activities, shipment processing activities, etc.

PRO TIP:

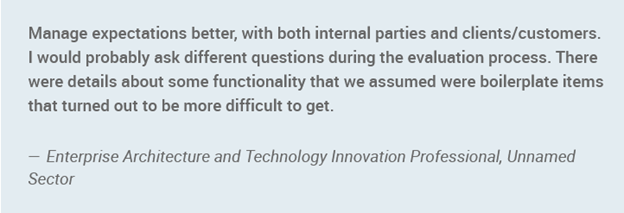

Enterprise WMS Implementation Lesson #2: Evaluate Vendors Based on Functional Requirements and Conduct Demos to Find the Right Fit

“Peer reviewers believe that a successful implementation is based on two factors. First, it is essential for the WMS to fit the operational environments of an organization’s warehouses. Second, it should align with current business requirements and future needs. Thus, to find the right vendor, peers advise scheduling demos of the proposed solution to test core functionality as well as any niche requirements.”

OUR TAKE:

The RFX you created should be shared with your enterprise WMS vendors so they can build a demonstration script that showcases the functionality that’s most important to you. There’s no need to sit through a demonstration that showcases functionality you don’t need. The RFX will easily determine what needs to be included and what can be left out, so you can gauge a true fit without being distracted by unnecessary ‘nice to have’ features and functions.

PRO TIP:

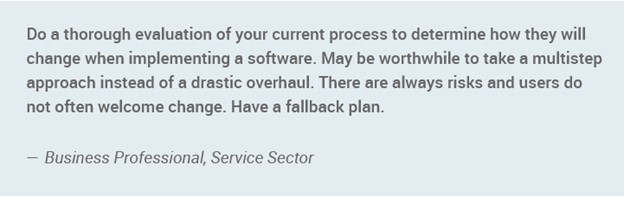

Enterprise WMS Implementation Lesson #3: Create a Robust Implementation Integration Plan and Prime the Warehouse Environment Before Deployment

“Most peers advise end-to-end mapping of warehouse processes and dependencies before the WMS is implemented. They recommend supply chain technology leaders to plan the implementation and integration timelines in advance for smooth deployment. Peers opine that the implementation strategy should be aligned with the vendor before launch.”

OUR TAKE:

Every project needs a plan, and that plan needs to be detailed and comprehensive. It should list all of the major activities required of the enterprise WMS software vendor, the system integrator and most importantly, the user organization.

PRO TIP:

Enterprise WMS Implementation Lesson #4: Facilitate Continuous Training to Upskill Users and Dedicate Internal Teams to Steer the Implementation

“A cross section of peers insists on developing WMS skills by investing in proper training for end users. Peers recommend supply chain technology leaders to dedicate teams that will be involved in knowledge exchange across warehouses, as well as in coordinating the implementation plan and timeline with the vendor.”

OUR TAKE:

The team at Made4net has been involved in countless enterprise WMS implementations. We know that success hinges on precision planning, training, and testing. Training should start at the beginning of the project and continue throughout – this includes initial vendor software orientation and setup, design discussions, conference room pilots, configuration of the software by operational project team members, development of standard operating procedures, and training programs, supervisory and end-user training, testing and startup.

PRO TIP:

Enterprise WMS Implementation Lesson #5: Hire an Experienced Implementation Partner and Leverage External Support for Seamless Integration

“A few peers advise to roll out the WMS as a minimum viable product (MVP), that is, with planned processes that meet core needs, while evolving the rest later. Peers unanimously agree to account for any additional lags during the go-live and the integration process. They further suggest that organizations must seek the expertise of an implementation partner to enable a smooth deployment.”

OUR TAKE:

Implementing a new enterprise WMS is something you might only do once in your career, and it’s a massive undertaking. While you know the ins and outs of your operation like the back of your hand, selecting and implementing a new WMS is likely not your forte, which is why hiring a professional to help with the process can be extremely valuable.

PRO TIP:

Download a complimentary Gartner report!

Reach out to our experts if you need help.