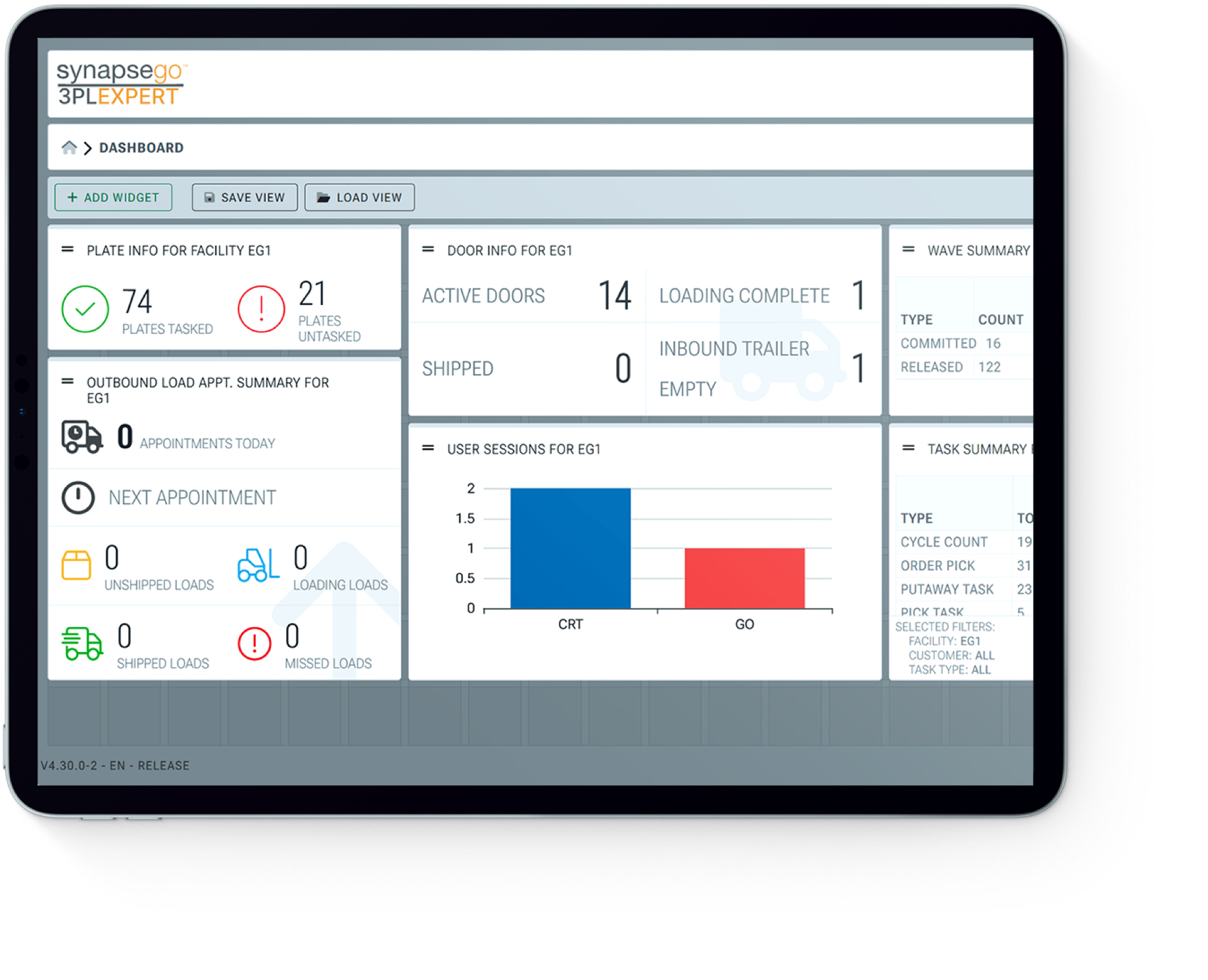

Synapse 3PLExpert

A 3PL warehouse management system built for modern operations

Everything You Need in a 3PL Warehouse Management System

Billing Granularity

Capture and automatically bill for every customer activity, including value-added services and other unique requirements.

Value-Added Services

Offer customers a suite of services—including kitting and assembly, labeling, repackaging and work order processing—that improve how they service their own customers.

Labor Management

Improve labor forecasting and increase efficiency through data capture activity with sophisticated reporting and data mining.

Adaptable and Scalable WMS designed to grow with your distribution needs

Returns Processing

Implement a simplified returns process that addresses customer replacement and manages inventory as required.

Reliable System Integration

Seamlessly integrate with financials and shopping carts, order management, ERP, parcel manifesting, warehouse automation and transportation management systems and share critical data through different levels of the supply chain with secure API integration.

Customer Portal

Provide customers autonomy over their orders via an easy-to-use web-based portal with which they can query their stock, inventory, flow, and throughput as well as their receipts and shipments.

Battle-Tested in Supporting High-Growth Industry Verticals

A Robust Warehouse Management System

What our customers are saying

Seamless Integration

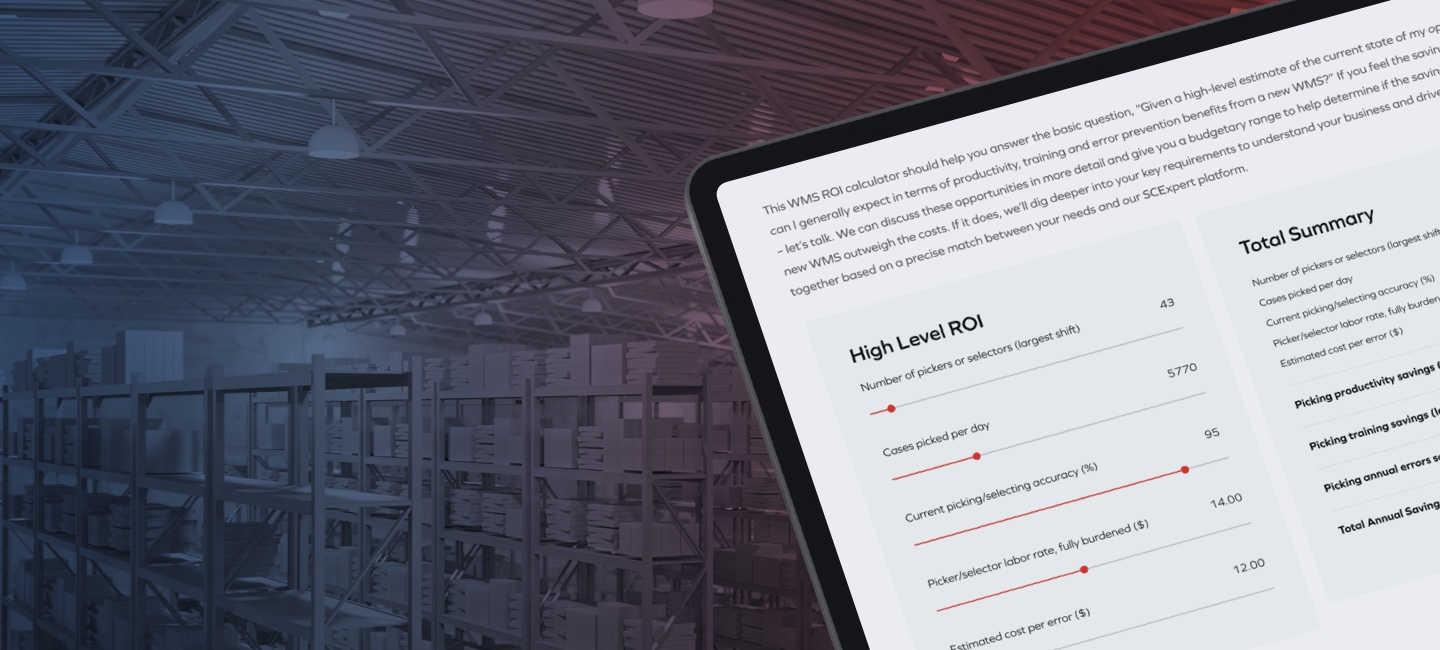

What’s your ROI?

Warehouse Management System FAQs

A Tier 1 warehouse management system is the most advanced solution for supply chain teams, handling complex operations across multiple facilities and integrations. It is highly customizable to meet specific operational needs.

A cloud-based warehouse management system (WMS) is ideal for businesses that prefer not to manage server hardware on-site, requiring only internet access to operate. Warehouse teams can use the web-based interface to run their operations.

Every facility has unique needs, but essential warehouse management features include:

- Flexible Integrations: The WMS should easily connect with carriers, suppliers, and other software like CRMs and ERPs.

- Automated Billing: The system should track activities by client, auto-generate invoices, and send them automatically.

- Analytics and Reporting: The software should offer robust, customizable reporting to deliver the right information, to the right people, at the right time.

- Ease of Use: The WMS should be user-friendly and adaptable to your unique needs with minimal source code changes.

- Billing Granularity: The solution should capture every revenue opportunity and ensure accurate billing by auditing operational processes, documenting each step taken for a customer, including value-added services, and aligning this data with customer contracts.

While many Warehouse Management Systems (WMS) can meet basic distribution needs, not all are designed to handle the complexities of a 3PL environment. A specialized WMS for 3PLs (3PL warehouse management system) offers features tailored to multi-client operations, such as the ability to manage diverse inventory across various clients, enhanced reporting capabilities, advanced billing functionality and seamless integration with other systems. These specialized solutions can provide the flexibility and scalability required to efficiently handle the unique demands of third-party logistics, ensuring better service levels and operational efficiency. Therefore, it's advisable for 3PLs to consider a WMS specifically designed for their industry to fully support their operational requirements.

The cost of a WMS can vary widely depending on factors such as the system's features, the size of your warehouse, and whether it’s deployed on-premises or in the cloud. Typically, WMS solutions can range thousands of dollars for basic systems to hundreds of thousands for more advanced, customizable solutions. Additionally, ongoing costs such as subscription fees, maintenance, and training should be considered in the total cost. It's essential to assess your specific needs and request quotes from multiple vendors for an accurate estimate. Our guide to warehouse budgets provides more information.

Choosing the right WMS involves several key steps:

- Assess Your Needs: Identify your specific requirements, such as inventory volume, complexity, and types of products.

- Evaluate Features: Look for essential features like inventory tracking, order management, reporting and analytics, and integration capabilities with existing systems.

- Consider Scalability: Choose a WMS that can grow with your business and adapt to changing needs.

- Request Demos: Evaluate potential solutions through demonstrations to understand their functionality and user interface.

- Check References: Speak with other users or read reviews to gauge the reliability and customer support of the WMS provider.

- Calculate Total Cost: Consider not only the upfront costs but also ongoing expenses, such as maintenance and support, to ensure the solution fits your budget.

Check this out in your analysis: The Gartner® Magic Quadrant™ for Warehouse Management Systems (WMS) is a one-of-a-kind report that uses a uniform set of evaluation criteria to help you quickly determine how well technology providers are performing against Gartner’s market view. We highly recommend incorporating this research into your search!