In today’s fast-paced, customer-driven supply chain, optimizing your warehouse is essential—not optional. Whether you’re fulfilling eCommerce orders, managing retail replenishment, or running a 3PL operation, the right warehouse management system and supporting tools can transform your facility into a high-performing hub. This guide to warehouse optimization software will help you understand the systems available, the benefits they deliver, and how to choose the best solution for your operation.

In this article, we’ll cover:

- What is warehouse optimization software?

- Types of warehouse optimization software

- Why is warehouse optimization software important?

- Common challenges in optimizing warehouse operations

- What are the main benefits of warehouse optimization software?

- What are the key features of warehouse optimization software?

- How to choose the best warehouse optimization software for your business

What is Warehouse Optimization Software?

Warehouse optimization software is a digital toolset that improves how warehouses manage inventory, people, space, and workflows. It helps streamline key processes like receiving, picking, packing, and shipping to boost speed and accuracy. By using real-time data and automation, it reduces errors, cuts costs, and increases productivity. These solutions often include warehouse management, labor management, slotting tools, and integration with other systems. The goal: faster fulfillment, better visibility, and a more efficient warehouse.

Types of Warehouse Optimization Software

The main types of warehouse optimization software include:

Warehouse Optimization Software #1: Warehouse Management System (WMS)

A WMS is the foundation of warehouse optimization. It manages the full range of warehouse activities, from receiving to shipping.

Key functions:

- Inventory control

- Order picking and packing

- Task management

- Space and slotting optimization

- Integration with ERP, TMS, and eCommerce platforms

Warehouse Optimization Software #2: Labor Management System (LMS)

An LMS focuses on labor productivity and workforce planning. It helps monitor performance, set engineered labor standards, and optimize workforce deployment.

Key functions:

- Labor tracking and reporting

- Productivity metrics

- Incentive pay programs

- Workforce forecasting and planning

- Gamification

Warehouse Optimization Software #3: Slotting Optimization Software

This software helps determine the most efficient location for each SKU in the warehouse based on factors like demand, size, weight, and pick frequency.

Key functions:

- Data-driven slotting analysis

- Simulation of pick paths

- Dynamic re-slotting recommendations

- Heat mapping of warehouse zones

Warehouse Optimization Software #4: Warehouse Execution System (WES)

A WES sits between the WMS and automation equipment. It optimizes task flow and coordinates activity in real time, often in highly automated environments.

Key functions:

- Order prioritization and release

- Conveyor and automation control

- Task orchestration

- Bottleneck resolution

Warehouse Optimization Software #5: Yard Management System (YMS)

A yard management system (YMS) manages trailer movements in the yard and at the dock. It helps prevent delays and reduces congestion at busy warehouse facilities.

Key functions:

- Gate check-in/check-out

- Dock scheduling

- Yard visibility and asset tracking

- Integration with WMS and TMS

Warehouse Optimization Software #6: Transportation Management System (TMS)

While not warehouse-specific, a TMS complements warehouse optimization by coordinating outbound logistics, mode selection, and carrier performance.

Key functions:

- Route planning and optimization

- Rate shopping

- Load consolidation

- Freight audit and payment

Warehouse Optimization Software #7: Inventory Optimization Software

This type of software focuses specifically on balancing inventory levels across warehouses to reduce stockouts and carrying costs.

Key functions:

- Demand forecasting

- Replenishment planning

- Safety stock analysis

- Inventory positioning across the network

Warehouse Optimization Software #8: 3PL Billing and Client Management Systems

Tailored for third-party logistics (3PL) providers, these systems manage client-specific billing and operational configurations.

Key functions:

- Client-level reporting

- Activity-based billing

- Contract-specific workflows

- SLA tracking

Why is Warehouse Optimization Software Important?

Warehouse optimization software is important because it helps businesses run faster, leaner, and more accurately—especially in an environment where customer expectations are sky-high and labor is tight.

Common Challenges in Optimizing Warehouse Operations

Optimizing warehouse operations isn’t always straightforward—many businesses face recurring roadblocks that impact efficiency, accuracy, and scalability.

Warehouse Challenge #1: Inaccurate Inventory Data

When inventory records don’t reflect reality, it leads to stockouts, delayed shipments, and lost customer trust.

Warehouse Challenge #2: Inefficient Picking Processes

Poor pick paths, manual errors, and lack of real-time visibility can slow fulfillment and drive up labor costs.

Warehouse Challenge #3: Limited Scalability During Peak Demand

Without flexible systems and optimized workflows, it’s hard to scale up during seasonal spikes or labor shortages.

What are the Main Benefits of Warehouse Optimization Software?

Key benefits include:

Warehouse Optimization Software Benefit #1: Streamlines Complex Operations

Warehouses manage thousands (sometimes millions) of SKUs, orders, and tasks daily. Optimization software keeps all of this running smoothly—automating what used to be manual, time-consuming processes.

Warehouse Optimization Software Benefit #2: Improves Accuracy and Reduces Errors

Picking the wrong item or shipping late can cost you a customer. Software helps eliminate errors by guiding workers through optimized workflows and ensuring every step—pick, pack, ship—is tracked and verified.

Warehouse Optimization Software Benefit #3: Speeds Up Order Fulfillment

Fast fulfillment is no longer a nice-to-have—it’s expected. Optimization software accelerates operations by:

- Optimizing pick paths

- Prioritizing urgent orders

- Reducing handling time

- Coordinating labor and automation

Warehouse Optimization Software Benefit #4: Cuts Costs and Improves Margins

By boosting labor productivity, reducing inventory carrying costs, and minimizing rework or returns, warehouse software helps protect your bottom line—even during peak seasons.

Warehouse Optimization Software Benefit #5: Improves Inventory Management

It provides real-time visibility into inventory levels, locations, and movement—helping avoid overstock, stockouts, and unnecessary replenishments.

Warehouse Optimization Software Benefit #6: Delivers Data-Driven Insights

Optimization software doesn’t just execute—it analyzes. Dashboards and reports provide insights into:

- Cycle times

- Order accuracy

- Labor efficiency

- Bottlenecks, which helps leaders make smarter decisions and continuously improve.

Warehouse Optimization Software Benefit #7: Supports Growth and Scalability

Whether you’re expanding to multiple warehouses, adding new SKUs, or integrating automation, optimization software adapts to your operation—so you can grow without breaking your systems.

Warehouse Optimization Software Benefit #8: Enhances Customer Experience

At the end of the day, the goal is to deliver the right product, to the right place, at the right time. When your warehouse is optimized, customer satisfaction goes up—and so does loyalty.

What are the Key Features of Warehouse Optimization Software?

While features vary by solution type, most warehouse optimization tools focus on these core areas:

Warehouse Optimization Software Feature #1: Inventory Management

- Real-time visibility

- Stock location tracking

- Replenishment rules

Warehouse Optimization Software Feature #2: Order Fulfillment

- Optimized picking and packing

- Wave and batch planning

- Shipping and manifesting

Warehouse Optimization Software Feature #3: Labor & Task Management

- Productivity tracking

- Task interleaving

- Workforce planning

Warehouse Optimization Software Feature #4: Space & Slotting Optimization

- Intelligent product placement

- Travel time reduction

- Storage utilization

Warehouse Optimization Software Feature #5: Integration & Automation Support

- ERP/eCommerce connectivity

- MHE and robotics integration

- API and EDI support

Warehouse Optimization Software Feature #6: Analytics & Insights

- Performance dashboards

- Exception reporting

- KPI tracking

How to Choose the Best Warehouse Optimization Software For Your Business

Not all warehouses need the same tools. Here’s a quick guide to help you pick what fits your business:

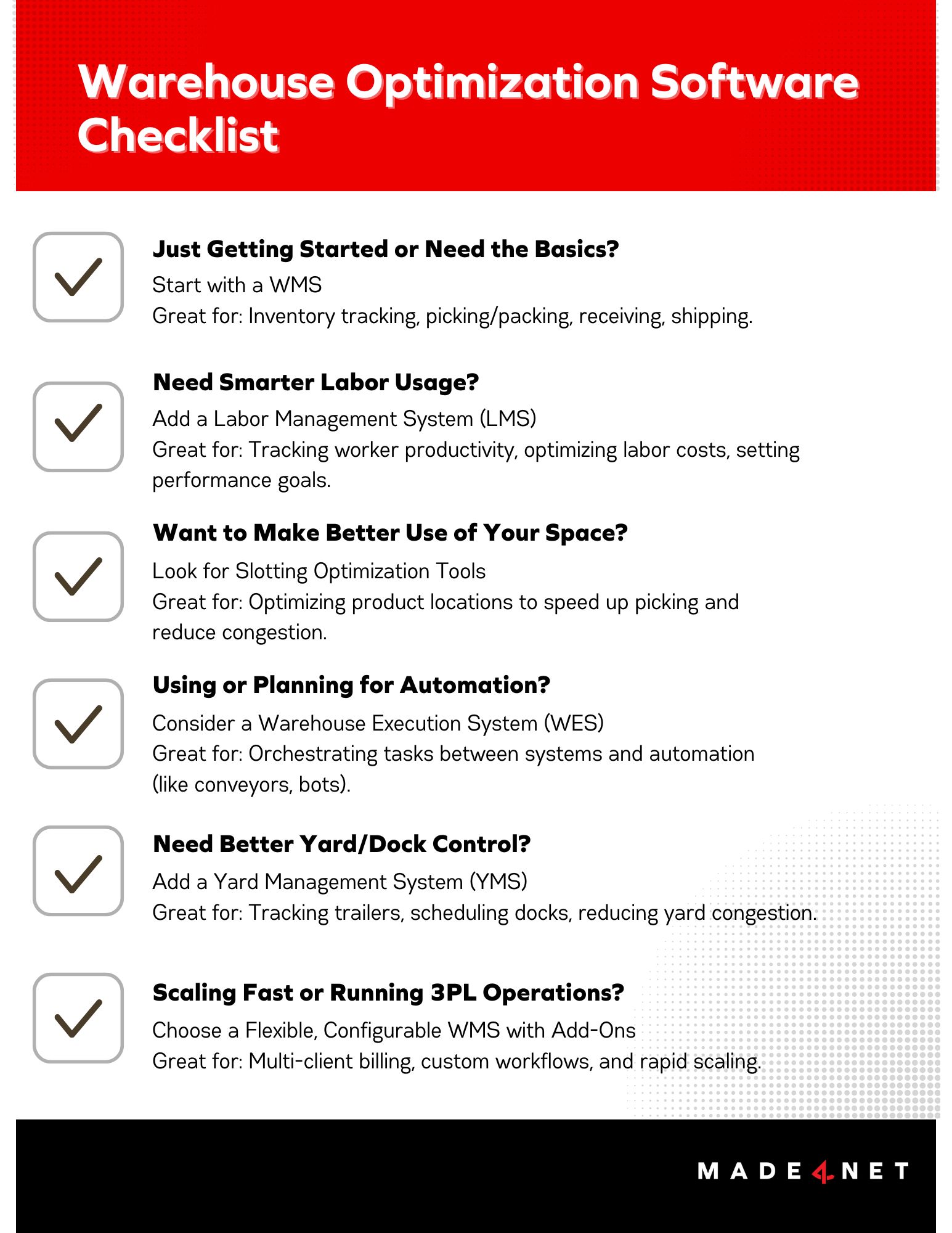

Just Getting Started or Need the Basics?

Start with a WMS

Great for: Inventory tracking, picking/packing, receiving, shipping.

Need Smarter Labor Usage?

Add a Labor Management System (LMS)

Great for: Tracking worker productivity, optimizing labor costs, setting performance goals.

Want to Make Better Use of Your Space?

Look for Slotting Optimization Tools

Great for: Optimizing product locations to speed up picking and reduce congestion.

Using or Planning for Automation?

Consider a Warehouse Execution System (WES)

Great for: Orchestrating tasks between systems and automation (like conveyors, bots).

Need Better Yard/Dock Control?

Add a Yard Management System (YMS)

Great for: Tracking trailers, scheduling docks, reducing yard congestion.

Scaling Fast or Running 3PL Operations?

Choose a Flexible, Configurable WMS with Add-Ons

Great for: Multi-client billing, custom workflows, and rapid scaling.

Need help figuring out your ideal mix? Made4net experts are here to help. Let’s talk.