If implementing a warehouse management system (WMS) has delivered many benefits to your operations, now it’s time to consider what adding automation can do to take things to the next level. With the growing complexity of warehouse operations, businesses are turning to automation to help with labor shortages, rising e-commerce demand, speed, and accuracy. Warehouse automation isn’t just about robotics; it also includes software, Artificial Intelligence (AI), and other solutions and system integrations designed to optimize efficiency.

In this post, we’ll explore what warehouse automation is, the different types of systems available, and how they can transform warehouse operations:

- What is warehouse automation?

- What are the benefits of warehouse automation?

- What are the challenges with warehouse automation options?

- What are the types of warehouse automation?

- How to implement warehouse automation systems or software

- What are the key trends and best practices in warehouse automation today?

- Getting started with warehouse automation

What is Warehouse Automation?

Warehouse automation focuses specifically on using machines and software to reduce manual labor and streamline repetitive tasks within the warehouse. It’s an elaborate mix of task-specific, technology-driven, and efficiency-oriented features that work together to improve the overall functioning of an operation. A simple example of warehouse automation is a warehouse with robotic picking systems and conveyor belts that move products efficiently through the facility.

Warehouse automation is not the same as smart warehousing. While it improves operational efficiency, it doesn’t necessarily provide higher-level decision-making or long-term adaptability. However, its benefits are critical to keeping up with the fast-paced supply chain environment.

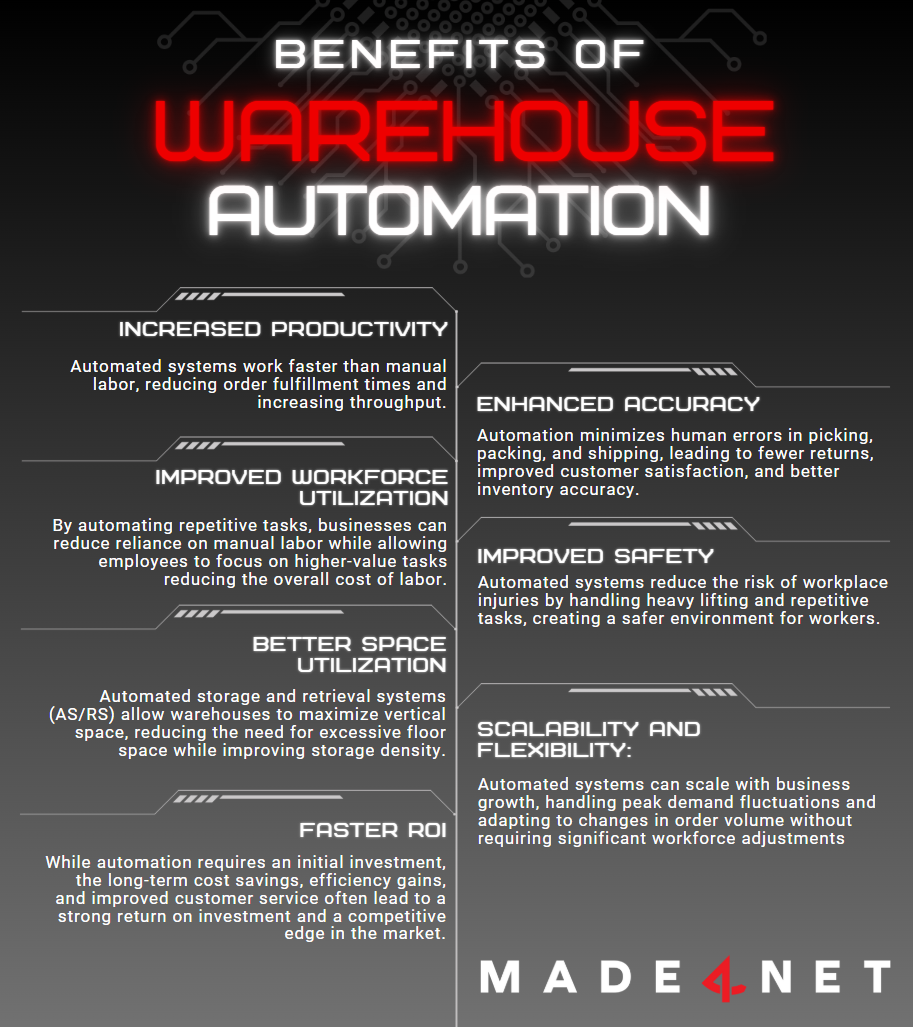

What are the Benefits of Warehouse Automation?

Warehouse automation offers numerous benefits that enhance efficiency, accuracy, and overall supply chain performance. With so many automation solutions available, they all play their part in helping operations remain nimble in a competitive landscape. The main advantages include:

- Increased Productivity: Automated systems work faster than manual labor, reducing order fulfillment times and increasing throughput.

- Enhanced Accuracy: Automation minimizes human errors in picking, packing, and shipping, leading to fewer returns, improved customer satisfaction, and better inventory accuracy.

- Improved Workforce Utilization: By automating repetitive tasks, businesses can reduce reliance on manual labor while allowing employees to focus on higher-value tasks like problem-solving and customer service, reducing the overall cost of labor.

- Improved Safety: Automated systems reduce the risk of workplace injuries by handling heavy lifting and repetitive tasks, creating a safer environment for workers.

- Better Space Utilization: Automated storage and retrieval systems (AS/RS) allow warehouses to maximize vertical space, reducing the need for excessive floor space while improving storage density.

- Scalability and Flexibility: Automated systems can scale with business growth, handling peak demand fluctuations and adapting to changes in order volume without requiring significant workforce adjustments.

- Faster ROI: While automation requires an initial investment, the long-term cost savings, efficiency gains, and improved customer service often lead to a strong return on investment and a competitive edge in the market.

Some automation solutions—such as conveyor systems, sortation, pick-to-light, and robotics—can function independently or with minimal system integration, but they work best with a WMS leading the charge. In warehouse automation, a WMS acts as the control center—coordinating automated systems, optimizing task assignments, enhancing visibility, and minimizing bottlenecks.

Warehouse automation offers significant benefits, but it’s important to discern what potential disadvantages may be associated with it, too.

What are the Challenges With Warehouse Automation Options?

While automation delivers undeniable benefits, it requires a substantial upfront investment in hardware, software, and infrastructure, making it essential for businesses to assess ROI carefully. However, cost isn’t the only consideration. Implementing and maintaining automation comes with additional challenges, including

- Seamless integration with existing WMS and supply chain technologies is crucial. Compatibility issues may cause inefficiencies and delays.

- Employees need training to work alongside automated systems. Resistance to change and a lack of technical skills can slow adoption.

- Automated equipment requires regular maintenance, and unexpected breakdowns can disrupt operations, leading to costly delays.

- As business needs change, automation solutions must be scalable and adaptable. Some systems may struggle to accommodate fluctuating demand or evolving operational requirements.

- Automation relies on accurate data for optimal performance. Errors in data entry or cybersecurity threats can compromise operations and efficiency.

- Relying on third-party vendors for automation technology means businesses must consider ongoing support, software updates, and long-term reliability.

While these challenges exist, careful planning, strong change management, and the right technology partnerships can help organizations overcome them and maximize the benefits of warehouse automation.

What are the Types of Warehouse Automation?

The beauty of warehouse automation is that there are a variety of options available, giving operations the opportunity to automate only what they truly need to optimize their operations. Generally speaking, warehouse automation can be categorized into several types, each designed to streamline operations, reduce manual labor, and improve efficiency. The main examples of warehouse automation include:

- Goods-to-Person (GTP) systems eliminate unnecessary walking and manual picking by bringing items directly to workers. Examples include:

- Automated Storage and Retrieval Systems (AS/RS): Computer-controlled systems that store and retrieve inventory with high precision.

- Carousel Systems: Rotating bins or shelves that deliver goods to operators, reducing picking time.

- Automated Guided Vehicles (AGVs): Follow fixed routes using sensors, magnets, or tracks to transport goods within a warehouse.

- Autonomous Mobile Robots (AMRs): Use advanced AI and machine learning to navigate dynamically, avoiding obstacles and optimizing travel paths in real time.

- Pick-to-Light systems allow workers to scan a barcode, which then prompts LED lights to direct them to the exact location of the item they need to pick.

- Put-to-Light systems work similarly to pick-to-light, but are used for sorting and organizing orders efficiently.

- Robotic picking systems use AI-powered robotic arms and vision systems to automate order picking, reducing the reliance on human labor while increasing picking accuracy.

- Voice-directed warehouse systems provide workers with verbal instructions via headsets, allowing for hands-free picking, packing, and replenishment tasks.

- Automated conveyor and sortation systems utilize high-speed conveyor belts and sortation systems to move products efficiently, directing them to the correct location using barcode scanning and software algorithms.

- Drones for Inventory Management: Drones use RFID and scanning technology to conduct cycle counts and inventory audits, reducing manual labor and improving accuracy.

Regardless of the kind of automation selected, a structured approach that ensures a smooth and effective implementation is critical.

How to Select and Implement Warehouse Automation Systems or Software

The first step in implementing automation is understanding what its purpose is. Operations should start first by assessing all current pain points. With that established, the operation must define what the objective of the automation will be, be it improving accuracy, increasing throughput, reducing labor costs, etc. This information will help businesses decide which type of warehouse automation will work best to address the identified pain points.

The following steps are recommended to ensure the best possible outcome:

- Conduct a Feasibility Study

- Evaluate warehouse layout, infrastructure, and compatibility with automation.

- Assess financial viability and potential ROI.

- Identify possible integration challenges with existing WMS, ERP, or other supply chain software.

- Define KPIs

- Set benchmarks to track performance before and after automation.

- Align KPIs with overall business objectives.

- Choose the Right Technology and Vendors

- Research automation providers and software solutions — The WMS selection process isn’t always easy, but there are helpful strategies to ensure you go down the right path.

- Consider scalability, maintenance requirements, and vendor support.

- Ensure chosen solutions integrate seamlessly with existing WMS or other management systems.

- Plan for Change Management

- Develop a strategy to gain buy-in from stakeholders and employees.

- Create an on-site team that will be focused solely on the new system integration.

- Designate a team member to be fully trained on the new technology so they can be the source-of-truth for others on-site to help out throughout the implementation.

- Address concerns about job displacement by focusing on reskilling opportunities.

- Communicate the benefits of automation clearly to the workforce.

- Pilot and Test the System

- Run a small-scale test before full implementation.

- Identify and resolve integration issues.

- Collect data to fine-tune performance.

- Train Employees and Optimize Workflows

- Provide training for employees on how to operate and maintain automation systems.

- Adjust workflows to maximize efficiency and avoid bottlenecks.

- Establish best practices for troubleshooting and system monitoring.

- Full Deployment and Continuous Improvement

- Gradually roll out automation across operations.

- Monitor system performance and track KPIs (e.g., order accuracy, processing speed, cost savings).

- Regularly update and optimize systems to adapt to evolving business needs.

This structure ensures businesses take a thoughtful, strategic approach to automation while minimizing disruptions. Warehouse automation implementations are complicated, and some businesses may opt to bring in a consultant to help with the process. This allows you to focus on your core responsibilities while they take on all the moving parts of a complex implementation process.

What are the Key Trends and Best Practices in Warehouse Automation Today?

Warehouse automation is evolving rapidly as companies seek solutions for rising labor costs and supply chain challenges. It comes as no surprise that one of the automation solutions growing in popularity is robotics. A recent survey shows that 46% of businesses now use robotics—double the rate from 2022—while 33% plan to adopt robots within three years.

Companies are primarily using robotics to address picking and packing, which remains a priority among operations. However, companies are also automating sorting, order consolidation, and trailer unloading. Another trend shows companies shifting to a hybrid automation approach, layering different technologies to optimize efficiency. Some are opting for Robotics-as-a-Service (RaaS) or hybrid CAPEX-OPEX models. However, ROI concerns, long project timelines, and the complexity of selecting the right solutions remain common hurdles.

For now, AMRs and goods-to-person systems are becoming industry standards, while piece-picking robots still face adoption barriers. Companies investing in automation must take a strategic approach to maximize efficiency, scalability, and ROI.

Getting Started with Warehouse Automation

Warehouse automation is no longer a luxury but a necessity for modern supply chains. As technology continues to advance, businesses that invest in automation will gain a competitive edge through increased efficiency, cost savings, and adaptability. However, successful implementation requires careful planning, the right technology partnerships, and a strategic approach. By staying informed on industry trends and leveraging automation intelligently, companies can future-proof their operations and meet the evolving demands of the supply chain landscape. If you’d like to learn more about how Made4net customers are using automation, reach out to our automation experts.