Operational metrics play a pivotal role in enhancing the efficiency of warehouse operations. These metrics serve as crucial tools for monitoring, benchmarking, and identifying areas for improvement. At Made4net, we recognize the significance of efficient warehouse management and understand that the first step towards improvement is having access to accurate data on current operations. In this blog post, we will delve into the importance of operational metrics emphasizing the top metrics that can significantly boost warehouse performance.

The Significance of Warehouse Operational Metrics

Operational metrics allow organizations to set and monitor benchmarks, facilitating the identification of areas that directly impact operational costs and customer satisfaction. These metrics are unique to each operation, requiring careful consideration of which ones are essential for tracking. Beginning with factors that company management uses to measure performance, such as overtime, fulfillment speeds, and accuracy rates, can serve as a starting point.

Challenges in Selecting Meaningful Metrics:

The logistics function is inundated with metrics, but not all contribute to the desired performance outcomes. Warehouse leaders often track metrics that focus on irrelevant activities or fail to see how warehouse performance influences the broader logistics network and supply chain. To overcome this challenge, leaders must prioritize a core set of metrics that align with cost and service level objectives. This involves analyzing performance holistically, understanding the trade-offs between operational execution, cost optimization, and service delivery.

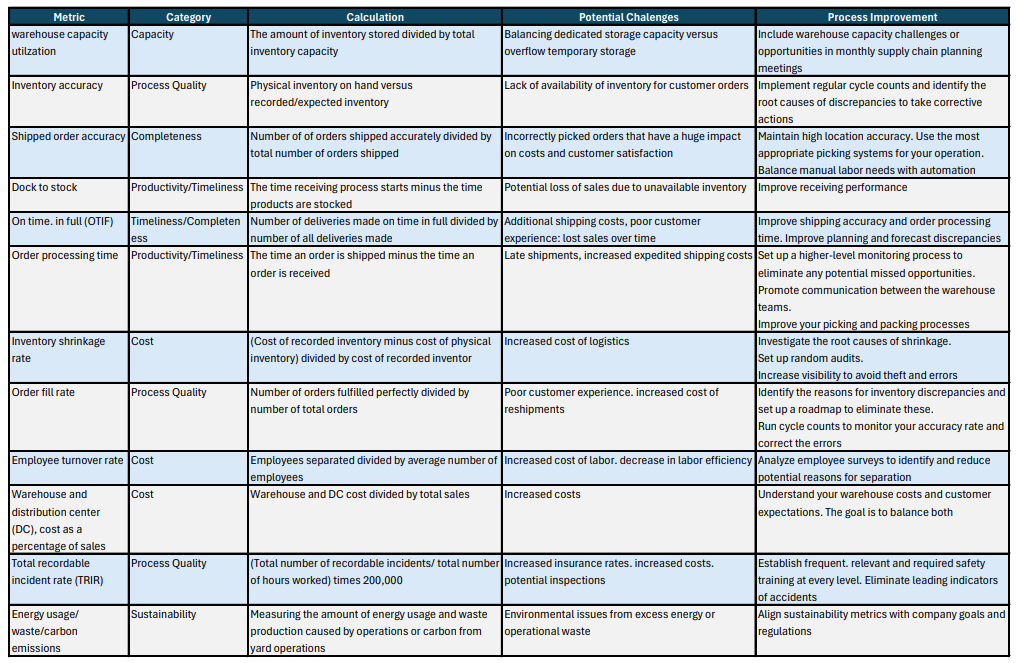

The recent report from Gartner: Use These Top 12 Operational Metrics to Improve Warehouse Performance identifies the top 12 most commonly used warehouse metrics, along with the method of calculation and the suggested process improvement resulting from each metric. The metrics “are organized into categories outlined within the hierarchy of logistics metrics as they apply to warehouse operation. These categories – timeliness, completeness, process quality, productivity, capacity, and cost – establish the framework for simplifying the capture of the foundational logistics metrics yet ensure a balanced view of performance is analyzed across the logistics operation.”

According to Gartner, the Top 12 Warehouse Metrics are:

- Warehouse Capacity Utilization

- Inventory Accuracy

- Shipped Order Accuracy

- Dock to Stock

- On time, in full (OTIF)

- Order processing time

- Inventory shrinkage rate

- Order fill rate

- Employee turnover rate

- Warehouse and DC cost as a percentage of sales

- Total recordable incident rate (TRIR)

- Energy usage / waste carbon emissions

To view the top 12 warehouse metrics along with the calculation, potential challenges and recommendations for process improvement, download a copy of the report here.

Focus on Continuous Improvement:

Establishing your metrics is just the first step in operating a more effective warehouse though. To maintain efficiency and productivity in a warehouse, performing metric reviews is essential. As the real value of metrics comes from analyzing the metrics output and driving a continuous Improvement agenda. The Gartner Use These Top 12 Operational Metrics to Improve Warehouse Performance report also provides a framework for implementing a robust metric review.

The framework includes four steps:

Step 1: Prioritize Agenda

Step 2: Conduct Regular Metric Reviews That Drive Accountability

Step 3: Nurture a Continuous Improvement Mindset

Step 4: Use Data and Take Corrective Action

In Summary:

It is impossible to improve an operation that is not being measured, therefore it is imperative that the right metrics are chosen based on your operational goals. Once your metrics are identified, measurement must be done consistently and managed effectively. Many companies are realizing that their existing technology – including many traditional warehouse management systems – are not capable of handling the agile requirements and demand for real-time, actionable data. A modern warehouse management system (WMS) can help capture and measure the above-mentioned metrics. The better visibility you have into your operation, the quicker you can pivot and adjust processes to improve performance and take advantage of new opportunities.

Learn more today by downloading the latest Gartner report.